Cotton Wedge

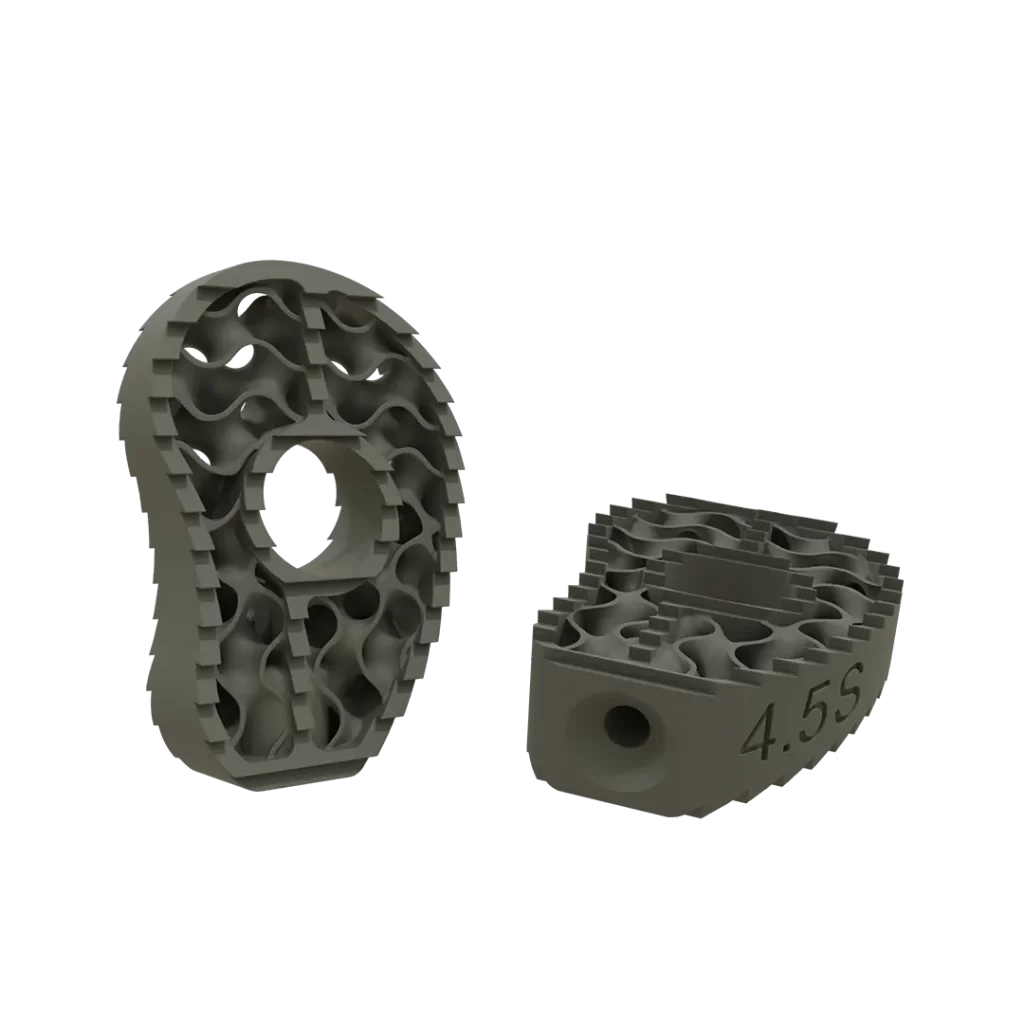

Our Cotton wedge system is a sterile, 3D-printed implant made from a biocompatible medical-grade Titanium alloy. It is specifically designed for fractures or osteotomies of the foot and ankle, ensuring superior internal bone fixation. Its porous structure enhances osseointegration by maximizing surface area to volume ratio and promoting greater interconnectedness, as supported by scientific research. Cotton wedges are utilized in various foot osteotomies, including opening wedge osteotomies and medial cuneiform osteotomies, particularly for the treatment of flatfoot. [1]

Product Overview

Product Overview

When Cotton wedges with TPMS porosity design are manufactured using biocompatible medical-grade materials and leading-edge 3D printing technology, the chances of a good surgical outcome are significantly enhanced.

Workflow

Imaging

To match the reduction surface with the wedge.

Product Manufacturing

3D printing technology is used to construct the wedge in different sizes with titanium, cobalt-chrome, and tantalum.

Surgery

The sterilized wedges in various sizes are given to the physician. An employee of our company may serve in the operating room to help with wedge placement.

Specifications

Based on the clinical evaluation of the patient and the desired course of therapy, surgeons and the engineering team always work together to develop the shape and features of the wedge.

To encourage bone ingrowth and osteointegration as secondary stability of the fixation, the base structure of these wedges may incorporate a TPMS lattice structure, such as gyroid because complex surface topography provides expulsion resistance and it will make a union.

These wedges allow for the customization of any design according to the doctor’s preferences, so they are developed in various footprint sizes and thicknesses to accommodate different patient anatomies.

Based on the intended inserter we threaded the hole to facilitate the wedge placement.

Specifications

Based on the clinical evaluation of the patient and the desired course of therapy, surgeons and the engineering team always work together to develop the shape and features of the wedge.

benefits

Lorem ipsum dolor sit amet, it amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem , luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Lorem kjsae ismcp ipsum

- Lorem ipsur sit amet

- fast and hard

- easy and flex

Cases report

The patient is a 31-year-old man diagnosed with pelvic osteosarcoma, who presented with...Read More

The patient is a 36-year-old man who has been diagnosed with pelvic sarcoma...Read More

The patient is a 22-year-old woman who has been affected by a Giant...Read More

The patient is a 49-year-old man who had previously undergone surgery and subsequently...Read More

Cases report

Our case studies illustrate the benefits that come from implementing our wedges. They demonstrate the effectiveness of our treatment plans and the ability of our staff to create unique solutions for each patient. Examining our reports may help you understand the level of precision and attention to detail we put into each and every aspect of our work with patient-specific wedges.