Customized TKA Guides

Complex deformities in the patient’s distal femur or proximal tibia or the existence of previous plates and screws on the patient’s bone would make revision surgery even more difficult. Using a 3D-printed customized guide would give better surgery results to the surgeon and the patient.

In addition, it should be mentioned that when it comes to complex deformities, customized surgical Guides would be a certain option to obtain the desired results.

Product Overview

Product Overview

Complex deformities of the bone, plates, and screws from previous surgeries, and defects of the bone in TKA revisions would be an issue for the physician. Customized TKA Surgical Guides will address these problematic surgeries.

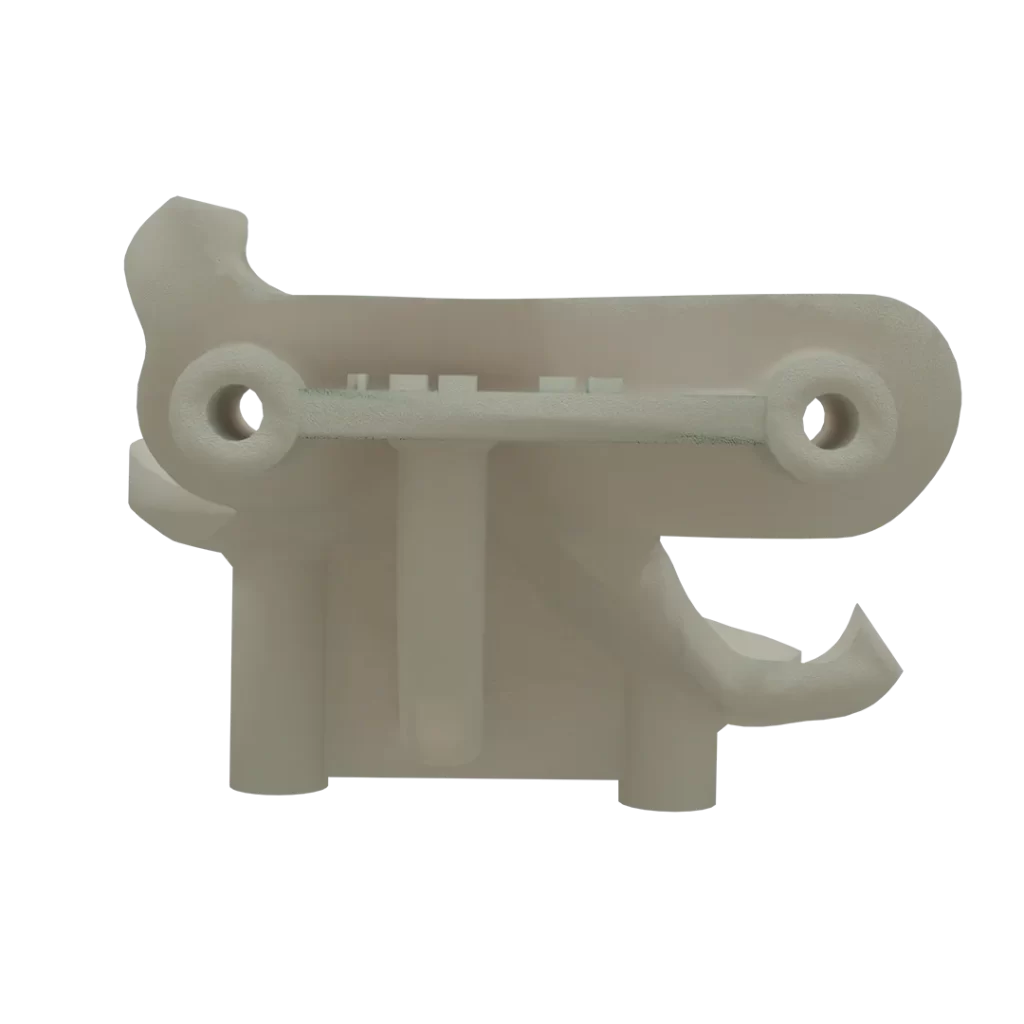

These guides are manufactured using 3D printing technology to help physicians by providing cutting planes for TKA surgery. They are designed based on the patient’s 3D bone model and this leads to a better surgical outcome and reduced stress for the surgeon as the cutting planes have previously been planned.

Workflow

Imaging

CT scan and X-ray imaging are acquired to create an accurate 3D model of the patient's lower extremity, and identify the complexity of the bone.

Pre-planning

Clinical engineers pre-plan the TKA surgery, in order to estimate the required prosthesis size and needing cutting planes.

Guide Design

Upon physician approval, the surgical guide will be designed by several biomechanical software. The guide is designed based on the patient’s deformity using 3D printing technology.

Surgery

The sterilized guide is delivered to the physician or the hospital and would be used on the bone at the surgery.

Specifications

Surgeons can collaborate with the engineering team to design the surgical guide based on their clinical assessment of the patient and the intended treatment plan.

Pre-planning provides the prosthesis size and the measurements of cutting bones to the surgeon while providing more detailed information about patient’s limb as well. This gives the physician the option of choosing the best surgical method for the patient.

By giving the cutting planes, customized guides reduce the surgical time which could be counted as an advantage for both the surgeon and the patient.

As well as reducing surgical time, customized guides provide higher precise outcome of the surgery, due to their “patient’s 3D bone modeling” design.

Specifications

Surgeons can collaborate with the engineering team to design the surgical guide based on their clinical assessment of the patient and the intended treatment plan.

benefits

Lorem ipsum dolor sit amet, it amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.Lorem , luctus nec ullamcorper mattis, pulvinar dapibus leo.

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

- Lorem kjsae ismcp ipsum

- Lorem ipsur sit amet

- fast and hard

- easy and flex

Cases report

The patient is a 31-year-old man diagnosed with pelvic osteosarcoma, who presented with...Read More

The patient is a 36-year-old man who has been diagnosed with pelvic sarcoma...Read More

The patient is a 22-year-old woman who has been affected by a Giant...Read More

The patient is a 49-year-old man who had previously undergone surgery and subsequently...Read More

Cases report

Our case reports highlight successful outcomes achieved through our custom-made implants. They showcase the effectiveness of our treatment plans and the expertise of our team in creating tailored solutions for each patient.

By reviewing these reports, you can gain a better understanding of the level of care and precision that we bring to every aspect of our work with patient specific implants.