According to ISNA on July 14, 2024, a leading knowledge-based company is providing customized orthopedic and CMF prosthetic services using advanced technologies such as laser-based 3D printers.

Dr. Morad Karimpour, CEO of the Fanavaran Jarahyar Sharif company and a faculty member at Tehran University, explained to ISNA that in their patient-centered service model, doctors collaborate with the company’s clinical experts to design and manufacture prostheses or guides tailored to the patient’s specific anatomy and the proposed treatment plan.

Dr. Karimpour elaborated that precise biomechanical analyses and simulations based on 3D imaging of the patient’s anatomy are conducted. This virtual simulation allows for the optimal treatment approach to be selected in collaboration between the doctor and engineers, ensuring that the best surgical method is applied.

He noted that the company’s products primarily cater to orthopedic and CMF surgeries and have gained the trust of numerous surgeons. The company has been instrumental in providing solutions for complex treatment plans.

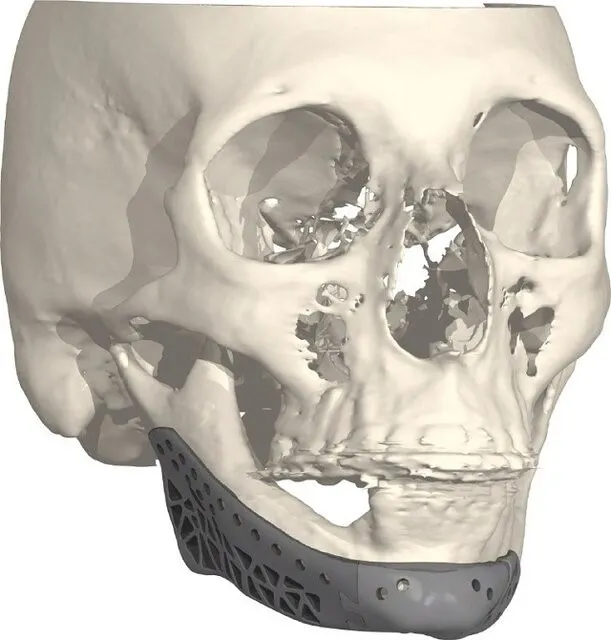

For instance, in orthopedic and facial tumor surgeries, custom-made prostheses improve surgical precision, reduce operation time, and enhance treatment outcomes. In a notable case from winter 2022, a patient with malignant chondrosarcoma in the pelvic area underwent surgery using a custom titanium prosthesis, preventing limb amputation. Additionally, a custom partial mandible prosthesis used in ameloblastoma surgery restored the patient’s facial geometry and allowed for dental restoration post-treatment.

Dr. Karimpour also highlighted that custom cranial prostheses for skull injuries enable precise design and optimal bone integration. The use of 3D printing with porous TPMS structures enhances bone in growth and stability between the prosthesis and the patient’s bone.

Other applications include porous titanium fusion cages for ankle surgeries, which promote bone growth within the prosthesis and ensure strong osseointegration with the patient’s bone.

Dr. Karimpour emphasized that the company’s research projects and graduate theses are closely aligned with the real needs of doctors, providing students with practical experience and training in interacting with medical professionals and developing products.

The close collaboration between doctors and the company’s research team has resulted in joint publications in international journals and professional associations. Since its establishment in 2013, the company has been a pioneer in custom surgical solutions, integrating biomedical engineers into the treatment process alongside surgeons and quickly achieving a prominent position among knowledge-based companies.

Dr. Karimpour added that having biomedical engineers in the operating room has addressed a critical gap in local healthcare, focusing on understanding and addressing doctors’ needs. The company’s philosophy centers on providing solutions based on a deep understanding of surgical challenges, enhancing the quality of care to meet international standards.

All clinical experts at the company are graduates from top universities, providing a platform for specialists to contribute to advancements in biomechanics and improve treatment quality.