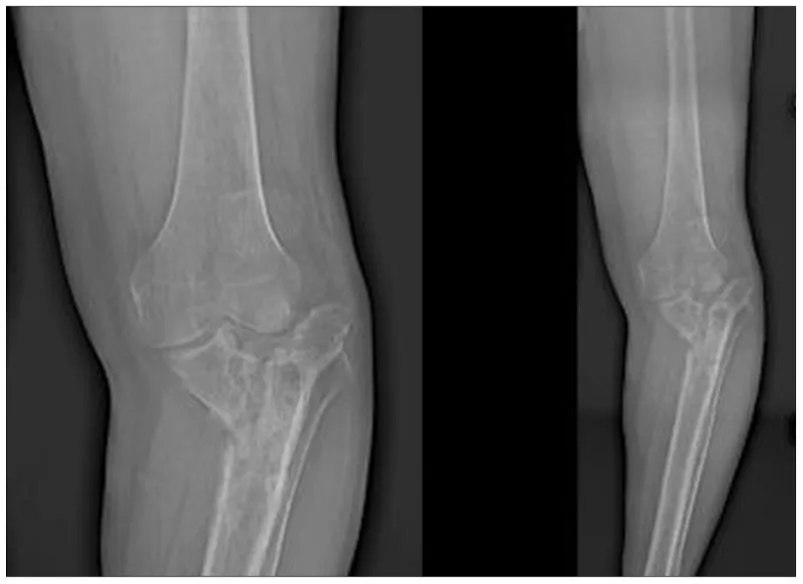

A 38-year-old male patient, following a previous fracture in the tibia and the non-union of the tibial bone, presented with a large bone defect in the proximal tibia and suffered from early osteoarthritis. He was a candidate for knee replacement surgery. Due to the presence of extensive bone defect, joint replacement was not feasible without the use of custom implants.

Pre-operative simulation and planning

After obtaining radiology and CT images and planning according to the physician’s treatment plan, a custom Cone was designed to reconstruct the bone defect.

After completing the planning and design, the custom-made implant was manufactured using 3D printing

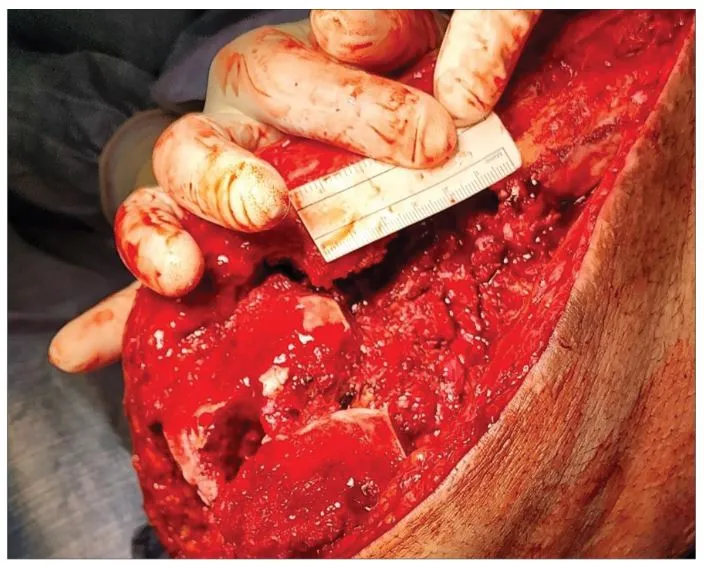

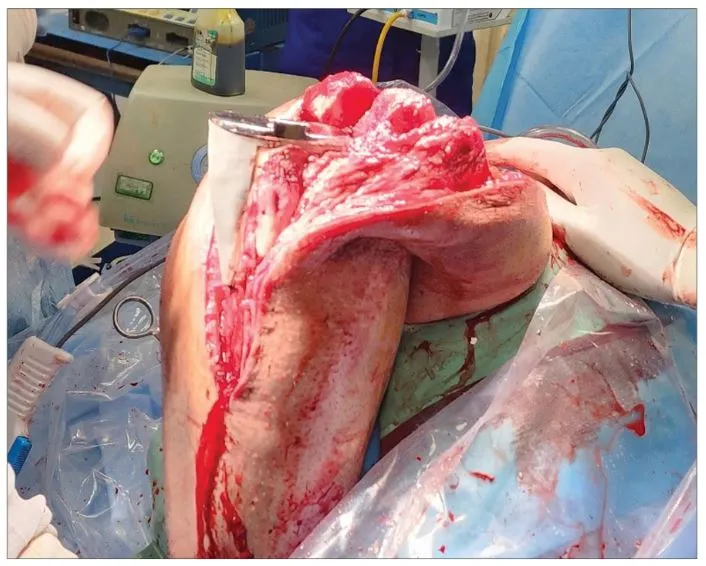

Surgical images

Based on the preoperative simulation, the prosthesis was positioned in the desired location. To ensure proper placement of the prosthesis, a trial component was used during surgery, followed by the implantation of the main component in the patient.

Prosthesis During Surgery

Images after surgery

The knee replacement surgery was successfully performed, and fortunately, after 15 months, the patient is in excellent condition.