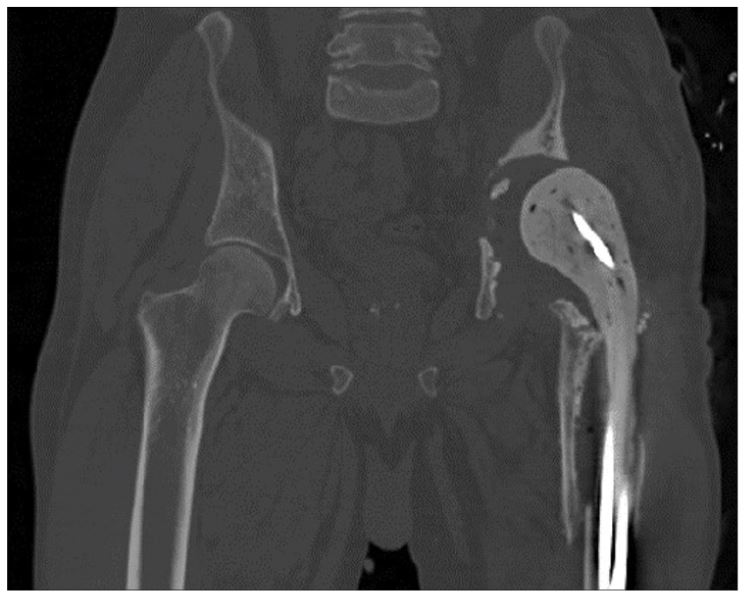

The patient is a 49-year-old man who had previously undergone surgery and subsequently had the prosthesis removed due to infection, after which a cement spacer was placed for him.

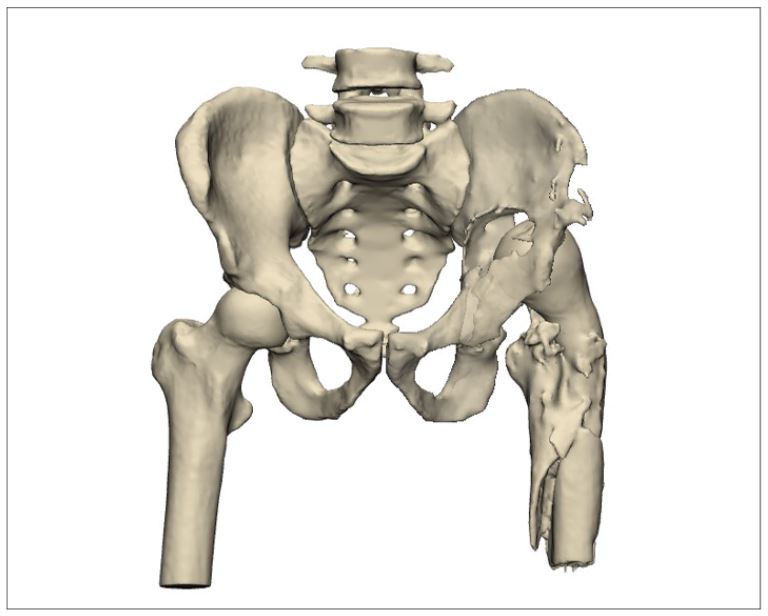

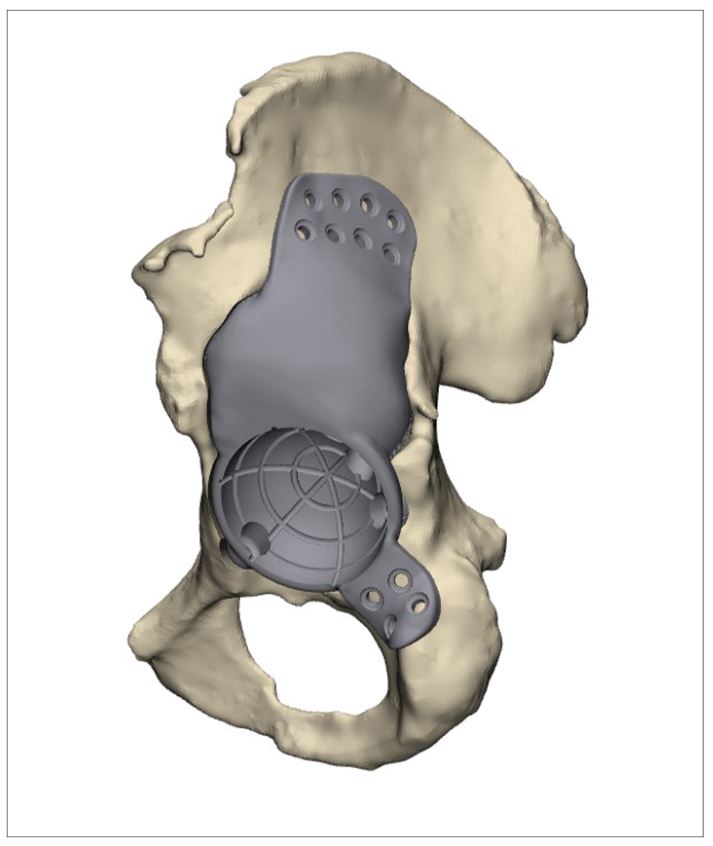

Pre-operative simulation and planning

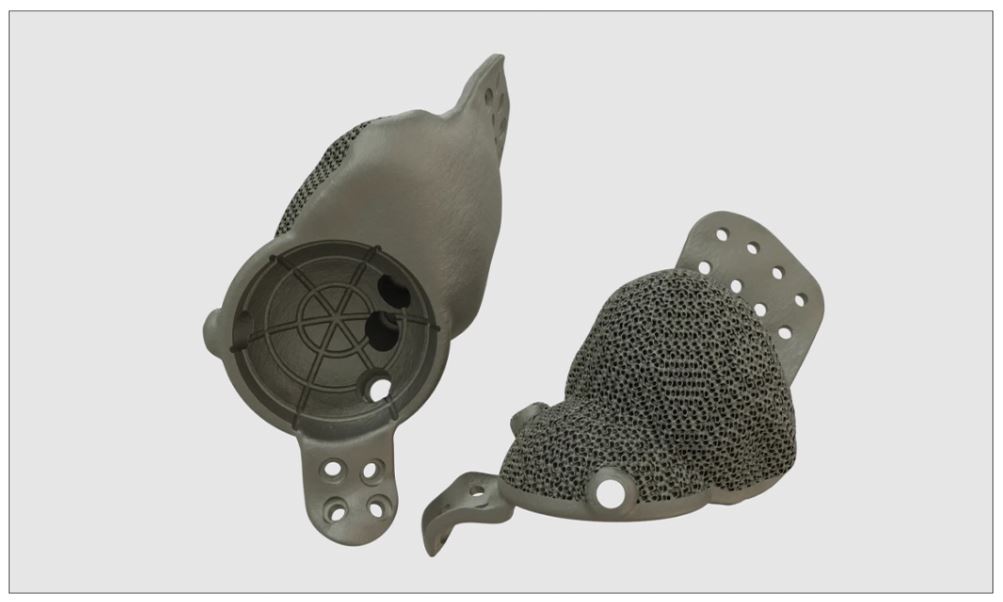

Based on the patient’s contralateral side, the overall geometry of the prosthesis was obtained. The version and inclination angles of the cup were also applied according to the patient’s healthy side. Positions for 3.5 mm screws were designated at the connection of the prosthesis to the ilium and ischium for prosthesis fixation. To ensure proper fixation, three 6.5 mm screw holes were created from inside the cup to fix the prosthesis to the wing of the ilium, along with one 6.5 mm screw hole for connection to the pubis. Additionally, a porous structure was created at the prosthesis-bone interfaces to promote bone tissue formation.

The part was manufactured using a 3D printer and, after post-processing, cleaning, and sterilization with gamma radiation, it was provided to the physician.

Surgical images

Based on the preoperative simulation, the prosthesis was placed in the desired location. To ensure the correct placement of the prosthesis, a trial component was used during the operation, and then the main component was inserted into the patient’s body as shown in the figure below.