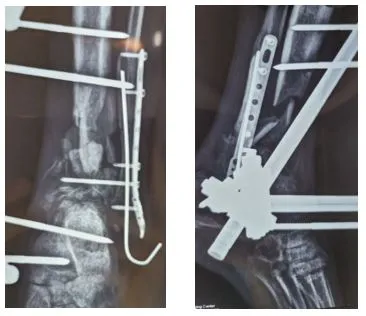

A 45-year-old male patient who had suffered a fracture and comminution of the distal tibia due to a traffic accident a year ago, presented to the physician after infection control and placement of an external fixator. However, the challenge for this patient was filling an 8-centimeter void in his bone.

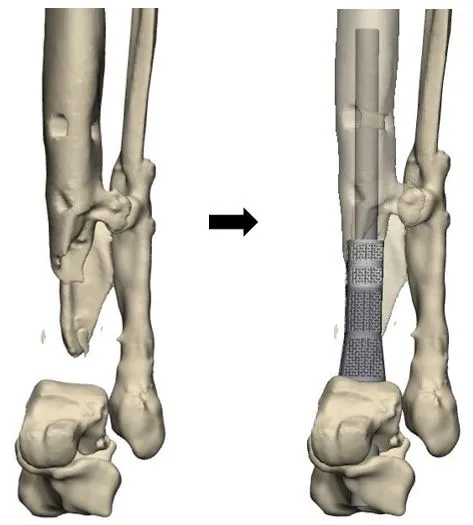

By analyzing the contralateral limb of the patient, the placement of the calcaneus was determined to prevent limb shortening, and the height of the prosthesis was established.

A channel for the passage of the Ankle Fusion Nail was incorporated into the prosthesis, and to facilitate filling the cage with autograft and ensure the strength of the piece, the prosthesis was designed with a porosity.

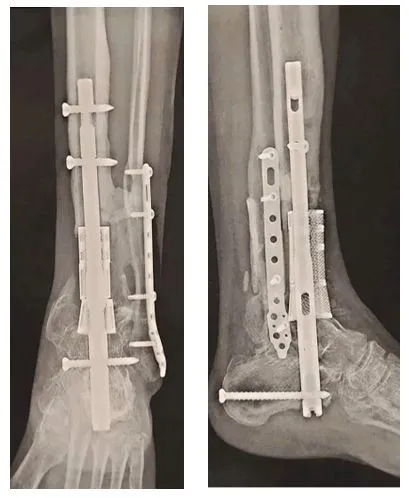

The prosthesis was manufactured using a 3D printer, post-processing operations, sanitization, and sterilization with gamma radiation, then it was delivered to the physician.