A 53-year-old female patient presented with a periprosthetic fracture. Due to multiple previous fractures resulting from an underlying condition and the failure of past surgeries, the defect in the distal femur was extensive. Additionally, the lack of sufficient bone stock for reconstruction presented another challenge in this case. Moreover, the patient’s unique anatomy, characterized by a very narrow femoral medullary canal, made reconstruction and revision joint replacement using standard prostheses and stems impossible. Ultimately, the use of custom-designed titanium implants enabled successful reconstruction and revision joint replacement.

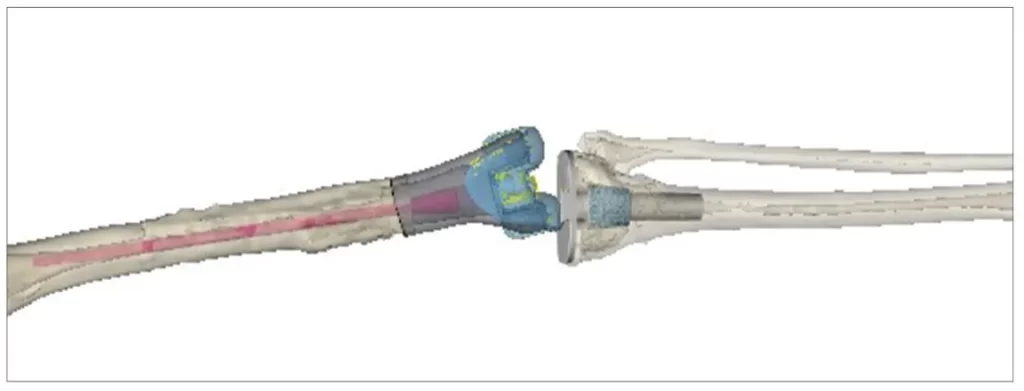

Pre-operative simulation and planning

Using the CT scan images, 3D modeling of the patient’s bone was performed. After planning and determining the patient’s treatment plan, custom implants were designed.

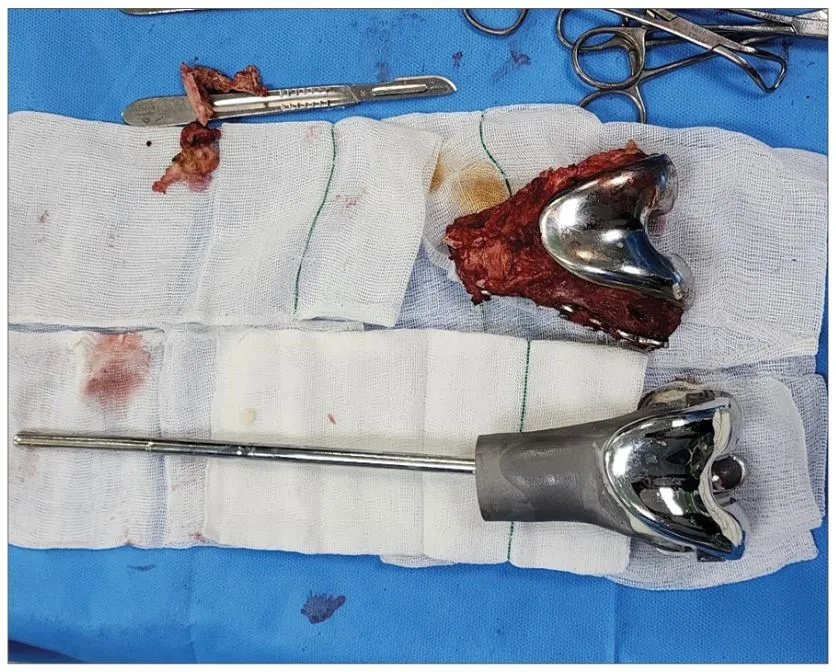

The component was manufactured using a 3D printer and, after processing, washing, and gamma sterilization, was provided to the physician.

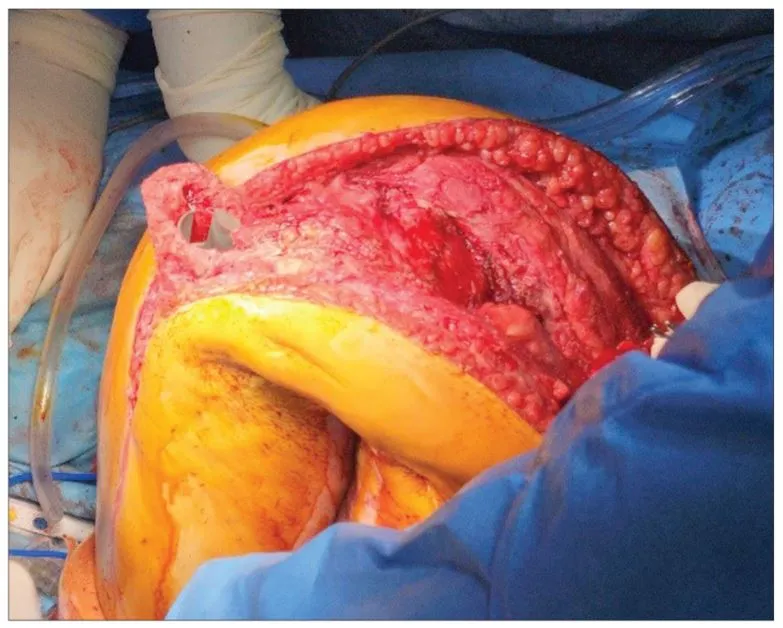

Surgical images

Implant Tailored to the Defect Size and Patient’s Anatomy”

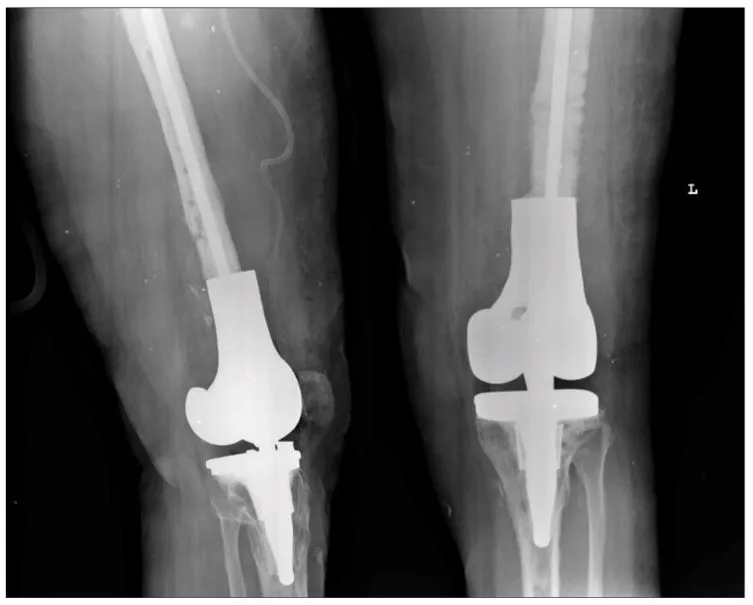

Images after surgery

he surgical outcome was highly satisfactory, and the patient’s bone defect was completely reconstructed. The patient was able to walk from the day after the surgery