According to reports from Mehr News Agency, ISNA, and the University of Tehran’s Public Relations Office, a custom mandibular prosthesis was successfully implanted on August 5, 2019, following a successful surgery. This prosthesis, developed through a collaborative research effort among researchers from Tehran University, Sharif University of Technology, and Tehran University of Medical Sciences, was created using 3D printing technology.

Dr. Morad Karimpour, a faculty member at the Faculty of Mechanical Engineering at Tehran University and CEO of Fanavaran Jarahyar Sharif Company, announced the news, stating that the patient had previously undergone a hemimandibulectomy due to a malignant tumor that caused the loss of half of their mandible. Based on the treating surgeon’s recommendation and the engineering team’s experience, it was decided to design and manufacture a custom-made prosthesis to restore the patient’s mandibular bone.

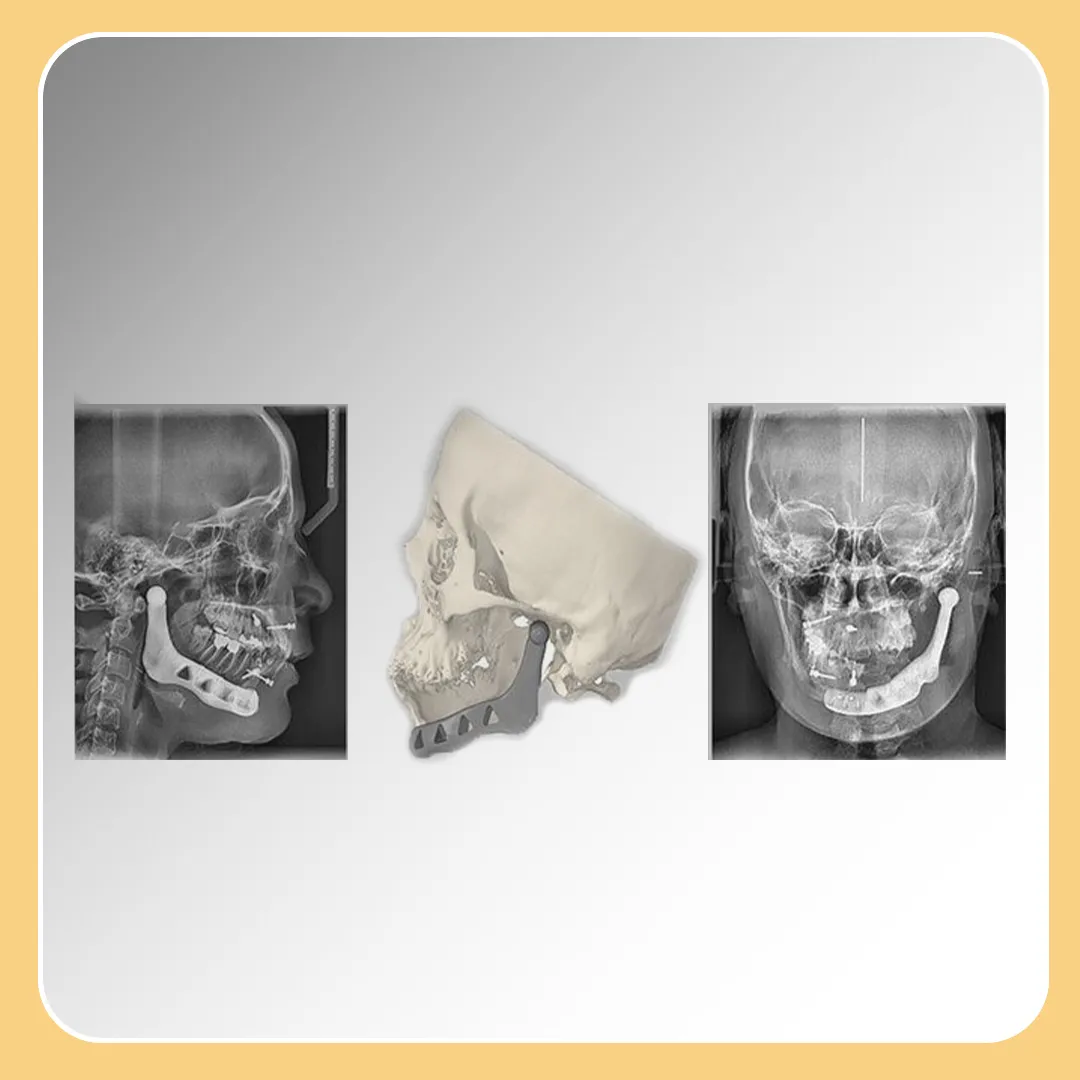

Dr. Karimpour explained that the prosthesis was designed based on the patient’s anatomical geometry and approved by the medical team. It was then produced using 3D printing technology with Selective Laser Melting (SLM) and medical-grade titanium alloy. Notably, the prosthesis includes the TMJ (temporomandibular joint), which is one of its innovative features.

After completion, the prosthesis was sanitized, sterilized using gamma rays, and implanted in the patient’s face during surgery at Sina Hospital. To ensure precise placement, the positioning of the prosthesis was verified using a Surgical Navigation System.

Dr. Karimpour also highlighted the team’s previous success in creating a custom mandibular prosthesis for a 70-year-old woman in February 2019. This achievement further underscores the team’s capabilities in developing advanced custom-made solutions.

The development of the custom mandibular prosthesis using 3D printing represents a significant accomplishment by the research team from Tehran University, Sharif University of Technology, and Tehran University of Medical Sciences.