3D printing technology has revolutionized medical science like other fields. For years, medical professionals have used bone moulage to better understand bone shape and help plan surgical procedures. However, traditional methods of creating these models are time-consuming and expensive, requiring complex machinery and a significant amount of manual labor. In this article, we take a look at the 3D printing method for making bone moulage

Applications of bone moulage

There are several key advantages to using bone moulage in orthopedic surgeries

a. Increasing accuracy: One of the most important advantages of bone moulages is increasing their accuracy. In traditional surgeries, surgeons must rely on their knowledge and experience of anatomy to account for changes in patient anatomy. By using bone moulage, the surgeon can see the exact structure of the bone, allowing them to more accurately plan and execute the procedure.

b. Better understanding of the patient: Bone moulages are very helpful for patients who may be struggling to understand the exact nature of their condition. Seeing a physical representation of their bone structure can help them better understand the surgical process and help them make informed decisions about care.

c. Advanced surgical planning: By providing a clear and accurate image of the bone structure, bone moulages can make surgical planning more efficient and effective. Surgeons can use this model to plan their surgical approach, which can potentially reduce patient anesthesia time, shorten surgical procedures, and lead to better outcomes.

d. Improving training: Medical students and residents can also benefit from working with bone moulage. The tactile experience of handling a physical model helps students gain a better understanding of anatomy and surgical procedures.

Making a bone model by 3D printing method

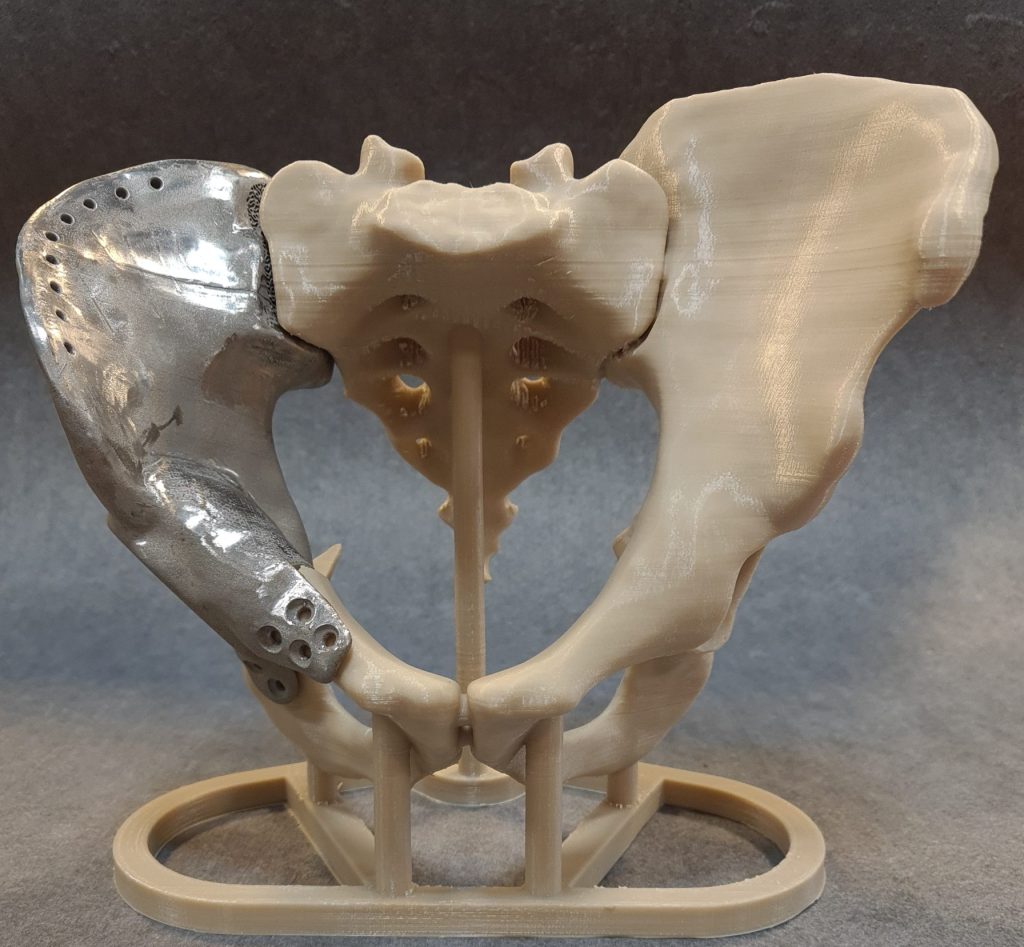

Thanks to advances in additive manufacturing technologies, 3D printing has become more accessible and affordable, making it more popular for producing bone moulages. The process of creating a 3D printing moulage begins with receiving the patient’s CT scan in layers. The CT scan of the patient is segmented in the special software and the necessary corrections and actions are performed on it. Then the 3D shape obtained from the previous step is converted into STL format and entered into the special 3D printing software. Then it is made in layers using suitable polymer materials such as polylactic acid.

Moulage custom prosthetics

With the help of moulage, doctors can fully familiarize themselves with the anatomy of the surgical site and the geometry of the prosthesis without opening the sterilized prosthesis and contaminating it, and even perform the surgical procedure in advance for better preparation.

Conclusion:

Today, the applications and methods of making bone moulage are essential for bone surgery. By providing accurate models of bone deformities or fractures, medical students can gain valuable experience in the art of bone surgery. In addition, surgeons can use these mockups to improve their preoperative planning strategies, thus speeding up interventions, defining techniques, and minimizing risk to the patient. In essence, bone moulages are vital to today’s orthopedic practice and continue to evolve as materials and technology advance. The manufacturing method and the materials used will continue to evolve according to the needs and applications for which they are needed. It is imperative that physicians embrace this technology and incorporate training strategies and anomaly simulation into their treatment approaches in order to achieve preoperative accuracy and superior surgical outcomes.

Preparation and compilation: Mohammad Karimi – production expert