Patient Information

At FJ Sharif, we specialize in personalized healthcare solutions that integrate advanced design and manufacturing processes. Our dedicated team collaborates closely with healthcare professionals to create custom medical implants tailored to your unique needs. From initial design concepts to final production, we ensure precision and quality, enhancing the effectiveness of your treatment and recovery journey.

Workflow

Finding a Doctor

Finding the right doctor is the first step towards personalized care. Our team helps you connect with experienced specialists who understand your condition and can recommend the best course of action for your health.

Scheduling a CT Scan

A CT scan is a crucial diagnostic tool that provides detailed images of your internal organs and structures. Our sales team ensures timely access to CT scanning services, allowing the medical team to accurately assess your condition.

Designing and Manufacturing

For cases requiring customized medical solutions, our engineering team collaborates with healthcare professionals to design and manufacture specialized implants. This personalized approach ensures optimal fit and functionality tailored to your unique anatomy.

Surgery

The physician with one of our team members perform procedures with precision and care. We prioritize patient safety and comfort, employing advanced techniques and innovative solutions developed through our collaborative approach.

Imaging Center

Explore Iran’s premier Imaging Centers, where cutting-edge technology and expert diagnostics come together to provide superior medical imaging services tailored to meet your healthcare needs.

Frequently Asked Question

After the patient is referred by the treating physician and the patient’s file is completed and the down payment is received, the necessary coordination is made for CT scan imaging or other types of medical imaging if needed. After conducting the initial review and approving the received images, a 3D model of the patient’s limb is extracted, and the initial treatment plan is implemented based on the physician’s request at the referral stage. The design is sent to the treating physician for approval. At this stage, if necessary and according to the physician’s request, modifications will be made; otherwise, the finalized design will be sent for the manufacturing process.

During the manufacturing process, the custom-made prosthesis will be printed by a 3D printer. After the required thermal operations based on the protocol, depending on the prosthesis’s usage, the part will be sent for final processing. Final processing includes secondary machining, coating, anodizing, or polishing the part at this stage. Finally, the part is sent to the cleanroom for sanitizing and packaging operations. In the last step, the packaged part is sterilized with gamma radiation and sent to the operating room with a technician.

The design and manufacture of custom-made prostheses, as indicated by the name, involves two phases. In the design phase, the time required depends on the patient’s promptness in completing the necessary imaging, as well as the time needed by the treating physician to approve or modify the design. Additionally, if the design undergoes changes, it is evident that more time will be needed.

In the manufacturing phase, the time required can vary depending on the dimensions of the piece and the urgency of the prosthesis’s use. The number and type of final processing operations also impact the time needed to manufacture and prepare the designed prosthesis.

On average, the design and manufacturing process for custo-made prostheses can take about 10 weeks from the time of referral by the physician. However, in most cases, the delivery time to patients has been shorter.

Currently, basic insurance plans do not provide coverage for custom-made prostheses. For supplementary insurance, it depends on the insurance company. In many cases, the insurance company, based on the physician’s request and an official invoice from the company, has covered part of the cost of the custom-made prosthesis according to the contract between the insurer and the insured.

Custom prostheses made using 3D printing technology are similar to those produced by traditional mass production methods. The main difference is that they are individually made and designed based on the patient’s anatomy. Therefore, in terms of risks and complications, these custom prostheses are exactly the same as conventional prostheses and plates.

Teaching materials

Osteoarthritis (OA), is the most common form of arthritis affecting millions worldwide. It ...

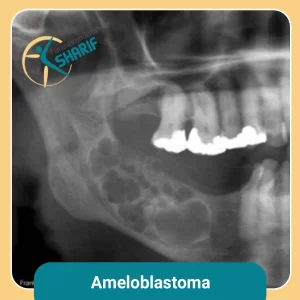

Ameloblastoma is a rare benign cancerous tumor that usually develops in the lower ...

3D printing technology has revolutionized medical science like other fields. For years, medical ...

Metal alloys play an essential role in the manufacture of customized prostheses. Metals ...

Teaching materials

Access valuable resources to empower your journey towards better health, including educational materials and patient support services.